Solution

Close

ADAS/Autonomous Driving

E-Mobility

Intelligent Cockpit

Body

Chassis Safety

Vehicle Network Communication

Full Vehicle

EOL

ADAS/Autonomous Driving

The development of Advanced Driver Assistance Systems (ADAS) and Autonomous Driving (AD) requires large volumes of data across the entire development lifecycle.VCARSYSTEM is committed to supporting customers in developing more reliable and innovative solutions by providing comprehensive services, including data acquisition and logging, data replay, system simulation, and validation.

Explore now

E-Mobility

VCARSYSTEM has consistently pursued excellence and innovation in automotive powertrain system R&D and validation through close collaboration with industry leaders. Focusing on core domains including engine management, transmission control, battery management, and motor control, VCARSYSTEM delivers end-to-end testing and validation solutions, ensuring superior product performance and an exceptional user experience.

Explore now

Intelligent Cockpit

With the rapid iteration of automotive chips, human-machine interaction, and automotive systems, VCARSYSTEM leverages its years of experience in the smart automotive field and full-stack in-house development capabilities to offer a range of cutting-edge testing products and tailored solutions. These solutions support engineers in efficiently completing tasks, particularly in areas such as smart cockpit testing and integrated cabin testing.

Explore now

Body

The body domain controller, serving as the control hub of vehicle beody components, plays a crucial role in ensuring the safety and reliability of the entire vehicle. Recognizing this need, VCARSYSTEM has integrated resources from research, testing, and experimentation teams to launch an efficient, versatile, and reliable automated testing solution for body domain controllers.

Explore now

Chassis Safety

Today, automotive chassis systems are becoming increasingly intelligent, with growing complexity in their system communication and functions. In response to this trend, VCARSYSTEM has launched a series of solutions covering steering, braking, suspension, and more, helping engineers conduct various tests and verifications on complex chassis control systems within limited resources.

Explore now

Vehicle Network Communication

The vehicle bus, as the core of automotive data communication, is crucial for ensuring the accurate, real-time, and secure transmission of information. To meet the high standards for reliability and security in bus systems, VCARSYSTEM provides a series of advanced testing solutions specifically designed for various bus systems, including CAN/CAN FD, LIN, FlexRay, and Automotive Ethernet, with the aim of optimizing the overall performance of vehicle communication systems.

Explore now

Full Vehicle

Vehicle testing is a comprehensive evaluation process that includes a series of rigorous and complex tests conducted from the design phase to pre-production launch, ensuring that the vehicle's performance, reliability, safety, and compliance meet design requirements and relevant regulatory standards. As a leading solution provider in the industry,VCARSYSTEM offers a range of innovative and efficient solutions tailored to the needs of vehicle testing. These solutions encompass everything from the development of testing equipment and optimization of testing processes to data analysis and processing, providing robust technical support and assurance for vehicle testing.

Explore now

EOL

We not only deliver industry‑leading testing systems, but also provide personalized and comprehensive solutions covering EOL detection, DV durability testing, and ECU flashing.Whether you're conducting foundational research or developing new products, VCARSYSTEM can provide precise, efficient solutions to help you achieve technological breakthroughs and innovations.

Explore now

Didn't find a suitable solution?

Get consultation

Product

Close

Hardware-in-the-Loop

Data Logger

Software

Network Communication

ECU Flashing & Diagnostics

HIL SYSTEM

Hardware-in-the-loop Test System

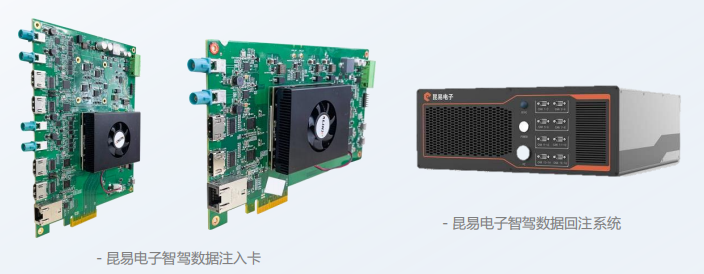

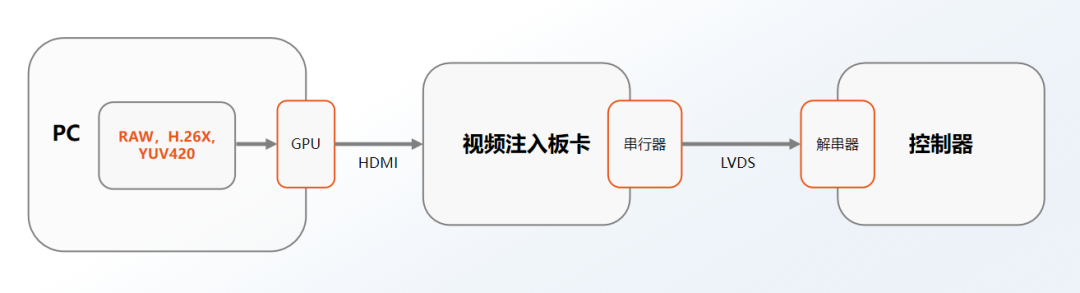

AUTOMOTIVE CAMERA INJECTION BOX

Camera Data Injection Module

REPLAY HIL

Automotive Sensor Data playback

CUBESTACK

Cloud Real-time Simulation Test System

MINI HIL

Desktop Hardware-in-the-Loop Test System

Rapid ECU

Rapid Prototype Controller

AD STATION SERIES

High-Bandwidth ADAS/AD Data Logger

VGATE SERIES

Vehicle Bus Data Logger

C MODULE

Data Acquisition Module

VCAR GMSL BYPASS

Gmsl Bypass Acquisitor

VIDEO BOX

Video Acquisition Module

VCAR DAS

Integrated SIL/HIL Testing & In-Vehicle Bus Development/Testing Software Platform

adSoft

ADAS Functional Evaluation Tool

vgSoft

VGATE Visualization Software

vgConfig

VGATE Configuration Software

WEB MANAGEMENT

WEB Management Platform

VCAR EM

Configuration Software

VCAR EA

Auto. Testing Software

VCAR MCD

ECU Calibration Software

VCI SERIES

Multi-Channel Interface for IVN

VBE SERIES

Multi-Channel Interface for IVN

VIT

Link Partner

KY-A2B

KY-A2B module

ECU Flasher

Engine Control Unit Flasher

OBD TESTING SYSTEM

On-Board Diagnostics Testing System

VCAR DAS

Integrated SIL/HIL Testing & In-Vehicle Bus Development/Testing Software Platform

Didn't find a suitable solution?

Get consultation

Contact us